GZL dry powder granulator

category:Granulation Equipment

product description:Extrusion granulation is a relatively new process of dry granulation to produce compound fertilizers. Extrusion granulation in the field of fertilizer used in the first granulation of potassium chloride, used for blending fertilizer (BB fertilizer) required granular (1-4mm) potassium chloride are basically used extrusion production. In recent years, extrusion granulation for the production of compound fertilizer in the country has been rapid development.

product description

Extrusion granulation is a relatively new process of dry granulation to produce compound fertilizers. Extrusion granulation in the field of fertilizer used in the earliest granulation of potassium chloride, used for blending fertilizer (BB fertilizer) required granular (1-4mm) potassium chloride are basically used extrusion production. In recent years, extrusion granulation for the production of compound fertilizer in the country has been rapid development.

Extruded granulation can be in the form of roller and roller type, the roller extrusion is first pressed into large pieces, and then broken into particles, so that the device capacity, high particle strength, low energy consumption, Roller extrusion is widely used abroad. Roller type is directly on the surface of the roll made of a groin-shaped shape, once squeezed into the formation of particles. Product strength is low and sometimes need to add adhesive. Suitable for organic fertilizer and fertilizer and other fertilizer.

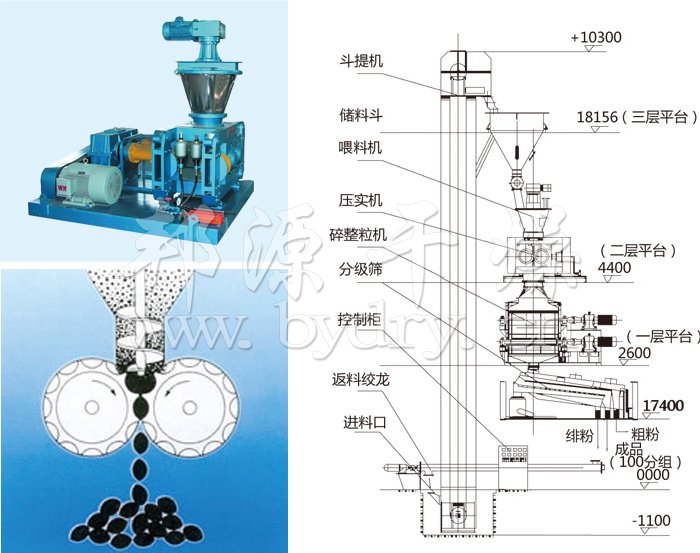

working principle

The principle of the roll extrusion granulation process is: dry material in the role of pressure under the reunion into a dense hard block (cake), known as the extrusion process; cake and then broken into a granular material called Granule process. The effect of squeezing is to squeeze the air between the particles, the other is to make the particle spacing close enough to produce such as van der Waals force, adsorption force, crystal bridge and embedded connections and other attractive. The granules of the extruded granules are mainly the strength of the particles formed by the force between the molecules.

Schematic

Technical specifications

|

model |

The center distance of the press roll |

power |

|

GZL-240 |

240 |

7.5-1.5 |

|

GZL-360 |

360 |

22-45 |

|

GZL-460 |

460 |

37-60 |

|

GZL-580 |

580 |

45-90 |

|

GZL-650 |

650 |

55-200 |

|

GZL-730 |

730 |

90-315

|